Uncategorised

Software Modules

You are offered various specialized software extension modules to increase the potential of the versatile eLitho and eDraw software:

|

|

|

|

|

|

|

|

|

|

|

|

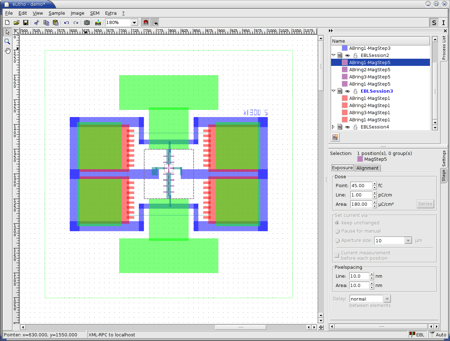

eLitho - Control Software

The graphical user interface for pattern arrangement and process control is especially suited to managing the challenges of R&D. You can use it to design all your process steps and test them offline. eLitho supports, in addition to eDraw, the planning and execution of multi-step lithography processes.

The software concept is based on the idea of a virtual counterpart to real sample on the main window of the program. This virtual sample is used to configure the lithography-process, to control its operation and to document the sessions.

-

Supported platforms: Windows 7, 8, 8.1 and 10

Supported platforms: Windows 7, 8, 8.1 and 10 -

Clearly arranged graphical user interface

-

Extremely flexible and clear parameter management; multiple lithography sessions consisting of arbitrary structures can be arranged, saved and loaded offline at which the parameters (dose values, dose series, pixel-spacing, delay between elements and alignment configuration) can be chosen freely

-

Full depth undo/redo functionality

-

Intuitive sample-adjustment feature for connecting the coordinate-systems of virtual sample and stage to allow for navigation and measurement

-

Automatic focus tracing for altering stage positions

-

Graphical process design and parameter configuration

-

SEM/FIB simulation for offline testing of the exposure

-

Direct integration of SEM/FIB and stage control

-

Image capture with brightness and contrast optimization; the images can be saved in various formats (TIFF, PNG, BMP or JPEG) and loaded again

-

Semi-automatic high accuracy alignment for multi-level lithography; maskable image acquisition, configurable coordinates of the marks and correction method

-

Visual process documentation

-

Automatic generation of session log-files

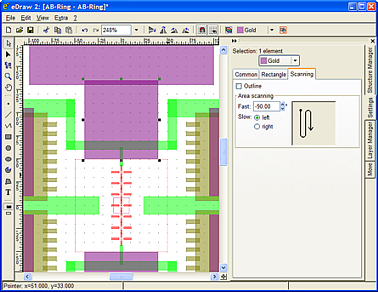

eDraw - Layout Editor

This elaborate CAD-tool provides you with the effortless creation of your lithographic structures even if they are quite complex. The editing features will assist you in designing multi-layer devices and in attributing lithography-specific parameters to the patterns. Some highlights of eDraw are:

-

Supported platforms: Windows 7, 8, 8.1 and 10

Supported platforms: Windows 7, 8, 8.1 and 10 -

Clearly arranged graphical user interface

-

Broad variety of provided elements: single points, single pixel lines, areas and outlines of rectangles, polygons, circles, circular arcs and ellipses

-

Bitmap import

-

Extremely flexible and clear parameter coordination

-

Comprehensive manipulation tools for editing the structures and defining exposure parameters of the single elements as well as their writing sequence

-

Full depth undo/redo functionality

-

Hierarchical structure management

-

Support of multi-layer structures and instances in order to create structural arrays according to the parent-child principle

-

Direct support of lithography specific parameters (e.g. scanning area, element order, dose series, element dose factors and scan parameters)

-

GDSII, CIF and DXF layout data import

Electron beam and FIB lithography

Electron beam lithography (EBL) and lithography with focused ion beams (FIB) are specialized techniques for creating micro- and nanostructures. A beam of electrons or ions is scanned in a well defined pattern across a surface. There are various methods to transfer the scanned patterns into the desired structure. In the case of the classical EBL the substrate is covered with a resist film sensitive to the electrons. The exposed structure can be developed (positive or negative) subsequent to exposure and be transferred by etching or deposition methods. In the standard operation mode of FIB lithography the ion beam removes atoms from the surface at the tiny spot where it hits the substrate (milling). Thus the pattern can be engraved directly into the material. In addition the electron beam as well as the ion beam can be applied for beam induced deposition of material supplied by an injected precursor gas. The main attributes of all these technologies are the very high resolution almost to the atomic level and the extraordinary flexibility which can be applied to a broad variety of materials and an almost infinite number of patterns.